Boiler Combustion

Furnace combustion modeling is done for number of reasons:

- Improving heat transfer

- Optimizing the burner flow distribution

- Reducing NOx and CO emissions

- See trends in furnace exit gas temperature (FEGT)

- Minimize LOI

- Avoid corrosion and slagging

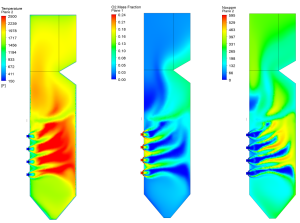

Burner air velocities and entrance angle are crucial for proper mixing in the combusting zone. Following picture is from a study which was performed for calculating general trends in NOx emissions for staged combustion in the means of introducing some portion of the combustion air at a higher elevation (OFA). Other NOx reduction methods are SNCR, low nox burners, water injection.

Front wall fired furnace - Temperature, Oxygen and NOx